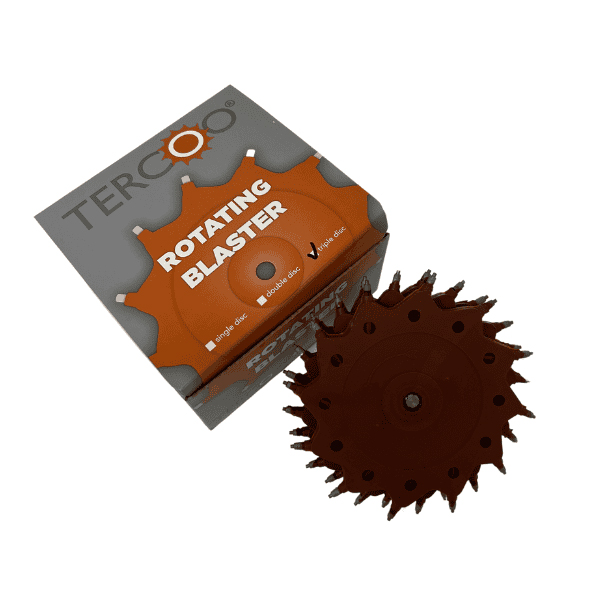

Wencon Rotating Blaster

Starting from $434.98

Rotating Blaster disc for removal of rust, dirt, paint and epoxy from materials, such as; steel, iron, metal, stone and concrete.

Rotating Blaster is a rotating disc for removal of rust, dirt, paint, epoxy etc. from various materials, such as steel, iron, metals, stone and concrete. Rotating Blaster is a rubber disc with 12 steel pins vulcanised inside, with an axle in the middle, for use in a hand drilling machine. The steel pins are made of special hard metal, mounted with conical shape. The disc is made of 96% natural rubber and is therefore very flexible. When the disc is rotating the pins are moving in different directions and the pins will hammer directly on the surface.

In situations where shot blasting is not possible, the Rotating Blaster is an alternative method for surface preparation. The blaster will leave the treated surface with a texture suitable for the application of a new protective coating. The hammer effect creates no heat, so tough materials such as tar, adhesives and sealants will be easily removed.

The Rotating Blaster discs are available as Duo and Triss discs for hand drilling machines.

– Excellent surface preparation

– Needle hammering with electric drill

– Best alternative to blasting

– Easy to use

– Long durability/service life

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Disc Quantity | PN# 1252 Duo, PN# 1254 Triss |